Published on :2020-04-15

When people talk about cars, the first thing they see is the body of the car, which represents the image features of the car. Therefore, automotive moulds are a general term for moulds used to manufacture all parts on automobiles. According to reports, it takes about 1500 moulds to manufacture an ordinary car, including nearly 1,000 stamping moulds and more than 200 automotive interior moulds. Chennuo Mould is a well-known automotive mould manufacturer in china, providing customers with high-quality automotive moulds, including high-quality plastic moulds for front and rear bumpers, mudguards, automotive lighting systems, dashboards, etc.

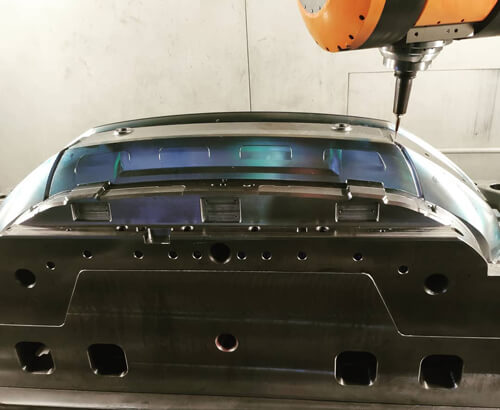

Today, many automotive manufacturers use plastic bumpers instead of metal bumpers when developing cars, which can effectively control development costs and shorten the entire bumper development cycle. Generally, the bumper area of the automotive is the most susceptible to collisions and scratches. If you use plastic bumpers, you can more effectively control automotive maintenance costs. Chennuo pays attention to the processing size of automotive bumper moulds and the matching relationship with bumper components. In the mould processing process, five-axis high-precision CNC machining equipment is used, and the process and parts of the automotive bumper mould are strictly controlled to ensure high-precision, high-quality automotive bumper moulds.

Automotive lamp moulds occupy a key position in automotive moulds. Automotive lamps are transparent parts that require high gloss, so the steel is generally stainless steel. Chennuo has imported advanced processing equipment, and its accuracy is beyond doubt.

For automotive dashboard moulds, automotive dashboards are parts that combine safety, functionality, comfort and decoration. First of all, the instrument panel needs to have a certain stiffness to support its components to ensure normal operation under high speed and vibration conditions: at the same time, it needs to have better energy absorption capacity to reduce external force alignment accidents when the following conditions occur. Therefore, the impact of a good automotive dashboard mould not only requires better product design, structural design, but also reasonable material selection.

Chennuo looks forward to your visit. If you are also interested in developing automotive moulds, please feel free to contact us. We will provide you with accurate transportation of high-quality plastic moulds and preferential prices.